Team of Stress Engineering Services, Origin, and nTopology earns 1st place in the USAF Advanced Manufacturing Olympics F-16 Approval Sprint Challenge

HOUSTON (Oct. 26, 2020) ─ The United States Airforce Rapid Sustainment Office has announced that the team consisting of Stress Engineering Services, Origin, and nTopology was awarded 1st place in the F-1 Approval Sprint Challenge. The announcement took place during the USAF RSO Advanced Manufacturing Olympics, which is a virtual four-day event held last week that includes five Technical Challenges focused on additive manufacturing and reverse engineering.

The goal of the F-1 Approval Sprint technical challenge was to identify innovative strategies for rapid design, qualification, and deployment of sustainment solutions which leverage new manufacturing materials, processes, and components.

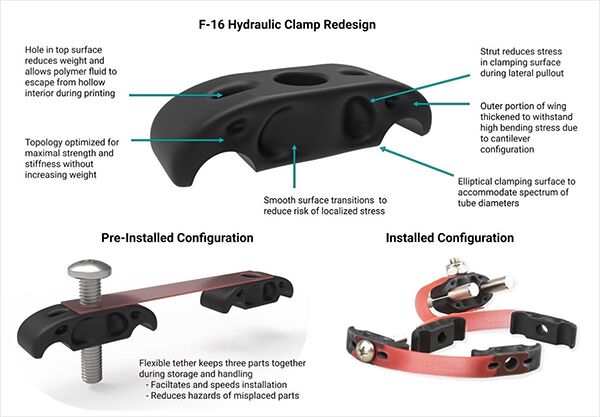

The winning team, which designed, analyzed, tested, and manufactured a multi-material F-16 hydraulic tube clamp, beat out stiff competition from 8 other teams from companies from National Institute for Aviation Research, Stratasys, and Markforged. The requirements for the challenge were quite complex and looked at dimensional accuracy, stresses/loads, flammability compliance, temperature ratings (low and high), jet fuel exposure, vibration tolerance, hydraulic fluid exposure, and engine oil exposure. The part submitted by the team for this challenge was designed on nTopology software, uses Loctite 3955, a flame-retardant chemically resistant material from Henkel, is manufactured on the Origin One 3D printer, and validated by Stress Engineering Services using an advanced rapid digital qualification process.

Matt Sanders, Stress Engineering Services team leader commented, “We were extremely grateful for the opportunity to participate in this challenge with Origin and nTopology. They are two outstanding companies on the cutting edge of AM technology. Our team was able to find ways to collaborate and be innovative together virtually during this challenging pandemic.”

“We look forward to working with the Airforce Research Laboratory and the Airforce Life Cycle Management Center to build out official Technical Data Package for an increasing amount of 3D printed parts,” said Chris Prucha, co-founder and CEO at Origin.

“We are honored and humbled by our first-place finish in the Approval Sprint Technical Challenge for the Advanced Manufacturing Olympics,” said Dr. Ryan O’Hara, Technical Director of Aerospace and Defense at nTopology. “Working alongside stellar teams at Origin and Stress Engineering Services proved to be both easy and rewarding. This is proof that combining all areas of expertise: design, analysis, and manufacturing can lead to unprecedented innovation and product design.”

###

About Stress Engineering Services, Inc.

Stress Engineering Services is a global leader in consulting engineering services and solutions that utilizes multi-disciplinary engineering methods, advanced technology, innovative applications, and a highly knowledgeable and experienced staff to provide understanding of risks and give confidence on how materials, process, and components perform through understanding the core scientific principles, advanced simulation/analysis, and qualification testing. Since 1972, Stress Engineering Services has been providing the most comprehensive design, analysis and testing services with an unsurpassed level of engineering integrity and skill. Stress Engineering Services is headquartered in Houston, with offices in Cincinnati, New Orleans, Calgary and Singapore. For more information, visit www.stress.com.

About Origin

Based in San Francisco, CA, Origin is pioneering the concept of Open Additive Manufacturing, a new way to build based on open materials, extensible software, and modular hardware. Origin One, the company’s manufacturing-grade 3D printer, uses programmable photopolymerization to precisely control light, heat, and force among other variables to produce parts with exceptional accuracy and consistency. The company works with a network of material partners to develop a wide range of commercial-grade materials for its system, resulting in some of the toughest and most resilient materials in additive manufacturing. The company was founded in 2015 and is led by alumni from Google and Apple. Investors include Floodgate, DCM, Mandra Capital, Haystack, TDK Ventures, Stanford University, and Joe Montana. Learn more about Origin here: https://www.origin.io

About nTopology

nTopology, headquartered in New York City, NY, is an engineering software company building the next generation of engineering design tools for advanced manufacturing. Their nTop Platform technology enables high-performance designs, lightning-fast iterations, and geometric complexity that were previously impossible to achieve. From its unbreakable modeling technology and field-driven design to remixable workflows guaranteeing repeatable outputs, nTop Platform empowers engineers and designers to create optimized parts meeting functional and performance requirements.