What is Ring Expansion Testing?

A guide for measuring full scale pipe material hoop yield strength using API 5L & ASTM A370

by: Matt Sanders, PE

The best way to move liquids and gases over long distances is via pipelines. Pipelines move oil, gas, and water under pressure. A pipeline’s ability to not permanently deform under pressure is critical and that property is called the yield strength. That is the stress level where a material stops springing back to its original shape and begins to change shape permanently. Operators keep pipeline pressures well below this point to maintain safety margins and long-term reliability. Because real pipe is formed, welded, sized, and cold-worked, its hoop (circumferential) yield strength can differ from textbook values or small lab coupons. That’s why we test: to measure how the actual pipe body behaves under pressure, so designs, integrity assessments, and regulatory limits rest on data, not assumptions. Ring Expansion Testing is the most direct way to do exactly that.

Ring expansion testing is a test method where internal pressure is applied to a full pipe ring section, and the circumferential (hoop/transverse) yield strength is measured. Specification API 5L recognizes ring expansion (by agreement between purchaser and manufacturer) as an accepted method for determining transverse yield, and ASTM A370 provides the test method and yield definition via Extension-Under-Load (EUL). It preserves pipe curvature and loading path, typically reducing scatter and aligning more directly with burst behavior than flattened test specimens.

Why/When to Use Ring Expansion

- Geometry & loading fidelity: Tests the pipe as a full section ring and loads it circumferentially in pressure. This more accurately represents the real-world conditions.

- Avoids flattening effects: Flattened test specimens can bias the yield strength to be lower through bending and Bauschinger effects; rings preserve curvature and prior strain state.

- Lower scatter: Eliminates coupon test specimen machining/flattening variability; often yields tighter distributions for hoop yield strength.

- Better indicator of burst strength: Ring-based yield strength trends correlate better with hydrostatic performance across pipe grades.

- Use cases: Vintage pipelines, coupon tests show slightly under spec, tight capacity margins, or when forming/sizing history is expected to distort flat-coupon results.

Sample Preparation and Test Setup

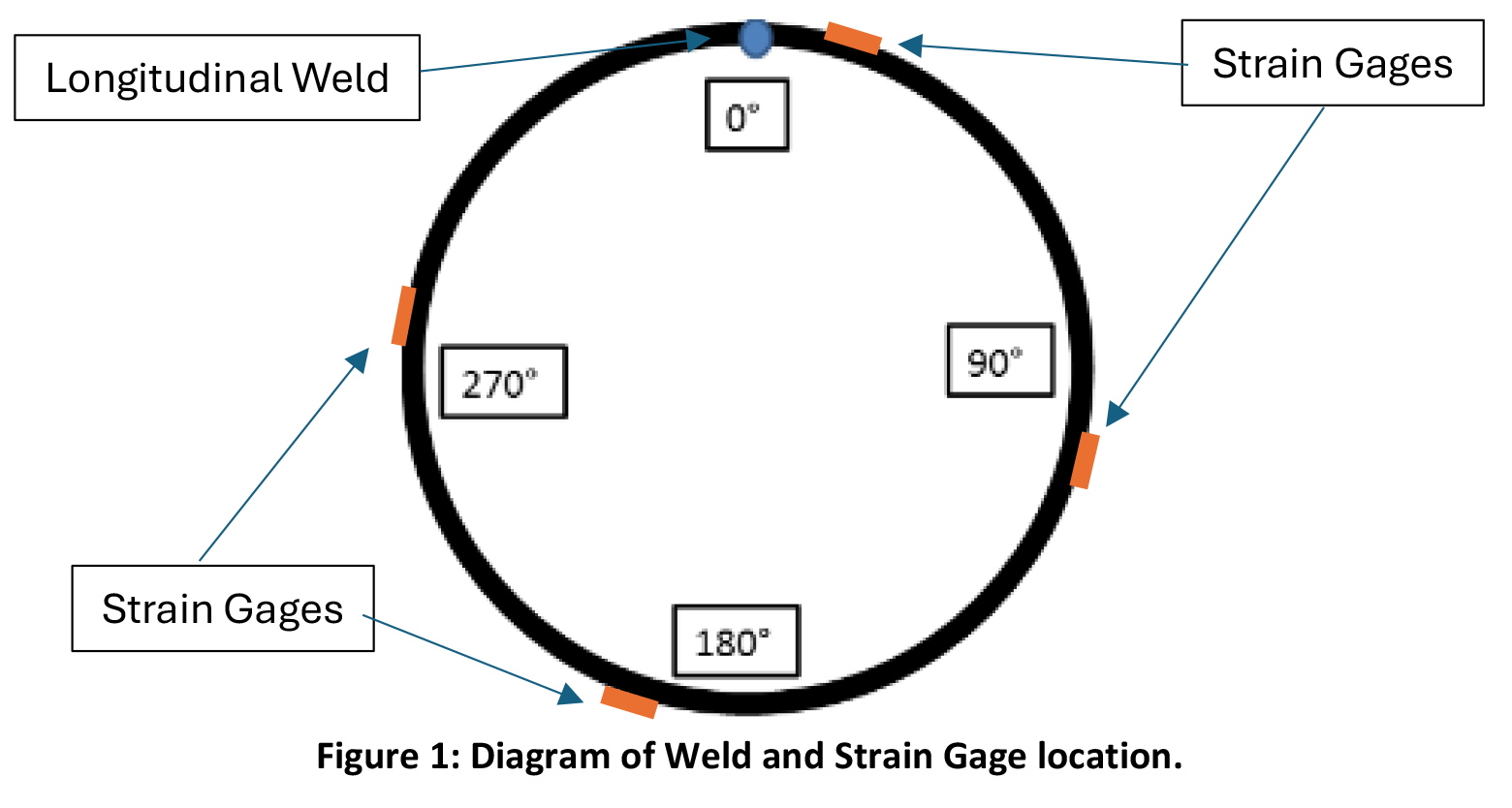

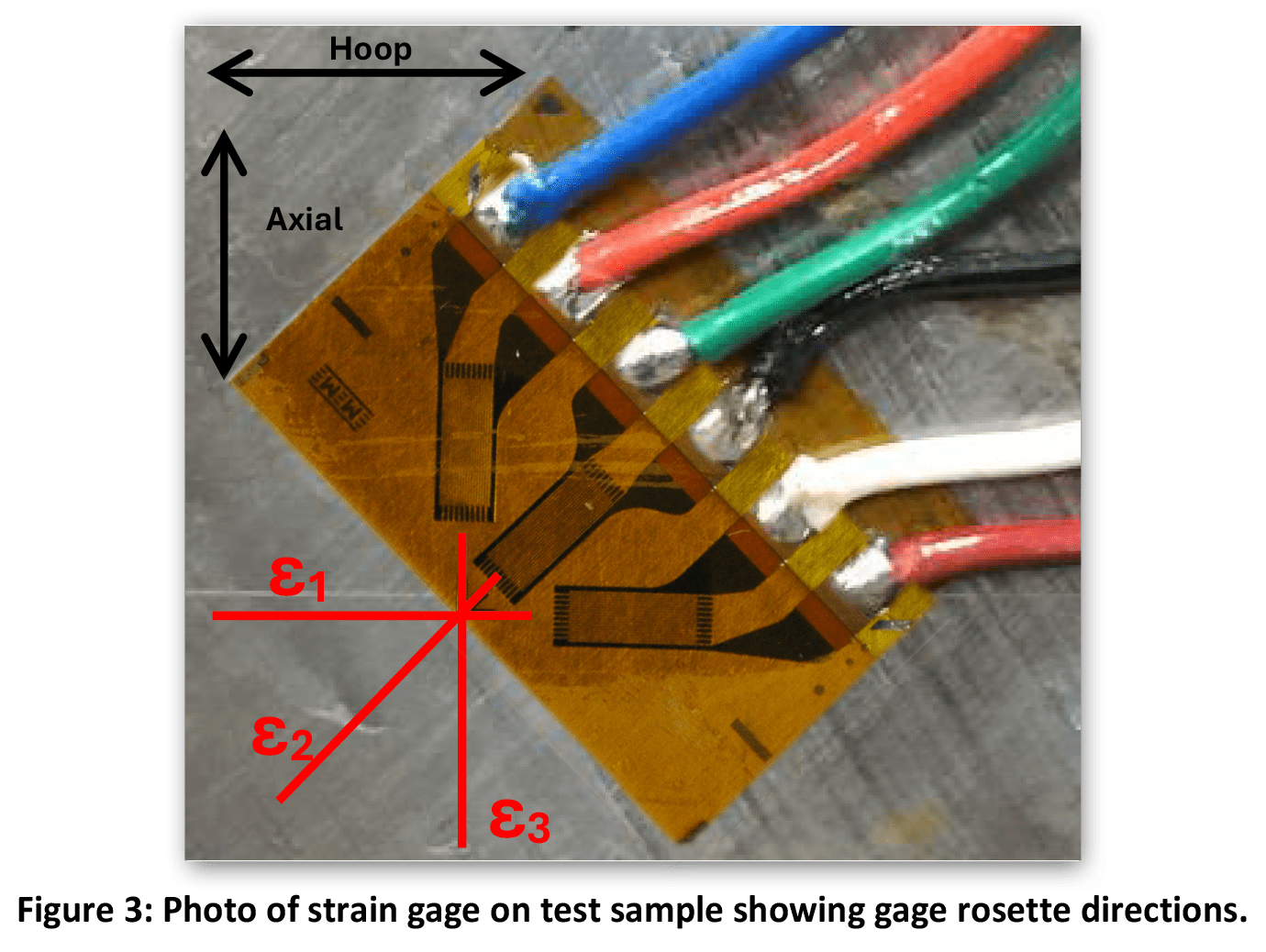

Prior to testing, raw pipe material is machined to an axial length of 3in with ends flat and parallel. After machining, tri-axial strain gages are installed every 90° at the sample mid-length as shown in Figure 1. The outer diameter (OD) and wall thickness at each gage location for each test sample are measured and recorded. A pi-tape measurement of the OD is also taken.

Testing

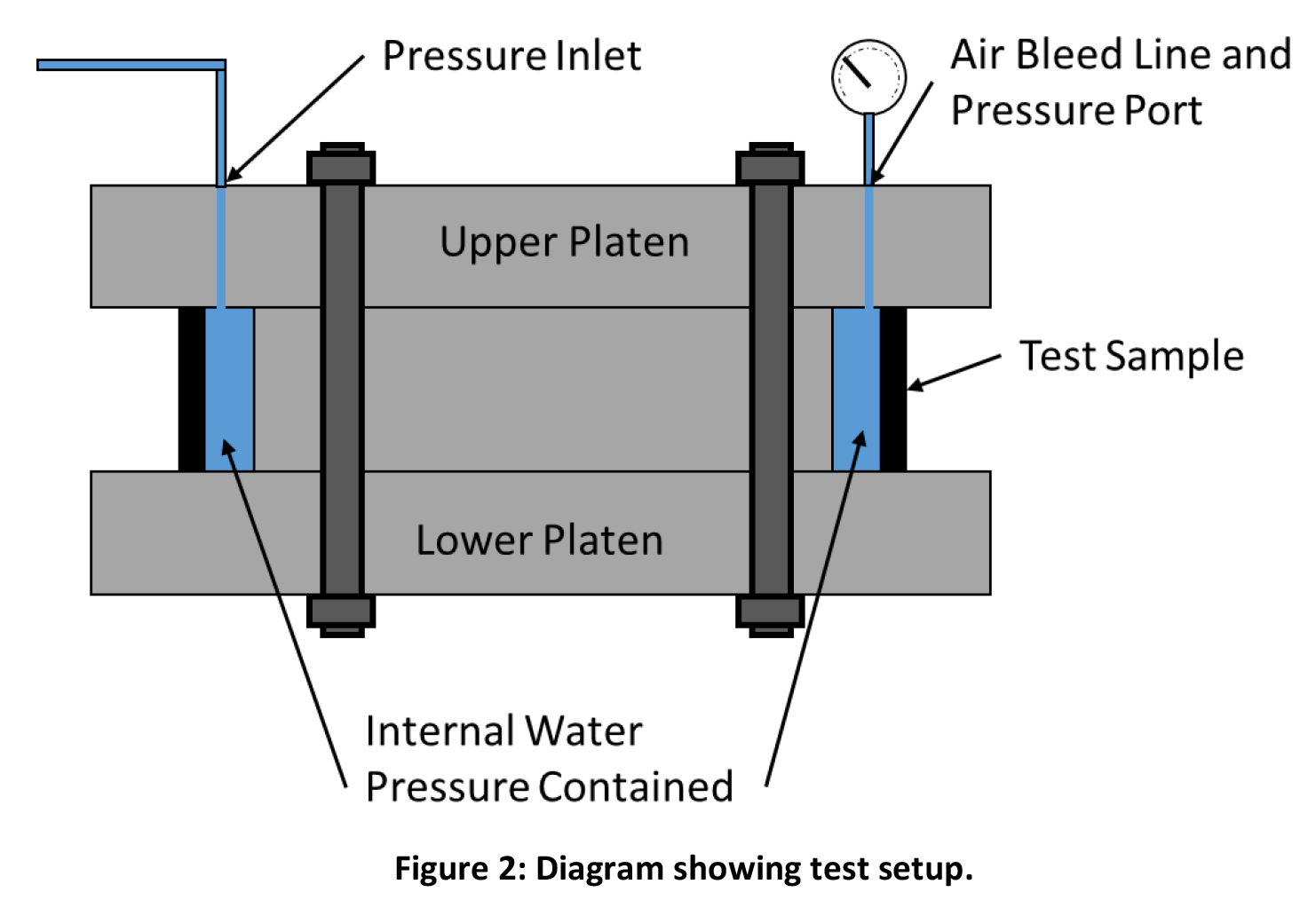

Testing is conducted in a ring expansion fixture as shown in Figure 2. The circumferential pipe deformation during testing is measured using both the strain gages and a chain extensometer. For each test sample, the test procedure consists of:

- Slowly increase water pressure while monitoring non-linear strain and displacement behavior via the data acquisition system.

- Once a satisfactory position beyond non-linear behavior has been achieved, release pressure and return to zero pressure.

- Ensure no pressure is active in the test fixture before disassembling the fixture.

Data Analysis

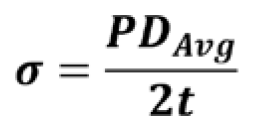

After each sample is tested, the test data is reduced and a calculated yield strength is determined from stress versus strain plots. For each test sample stress-strain plot, the stress can be calculated from the test pressure using Equation 1:

Where:

σ : Pipe stress

P : Internal Pressure during testing

DAvg : Average pipe diameter (OD – average wall thickness)

t : Pipe wall thickness

The strain is determined using either the chain extensometer as per ASTM A370 or from the strain gage measurements.

For the roller chain extensometer-based Stress-Strain plots, the chain extensometer measurements are correlated to the corresponding pressure at a sampling frequency of 1 Hz during testing. The extension should be corrected for the extensometer angle and converted to strain by dividing by the Pi tape diameter measurement for each sample.

For the strain gage based Stress-Strain plots, the data from each strain gage is correlated to the corresponding pressure. The stress is calculated in the same manner as for the chain extensometer shown in Equation 1, except the specific measured wall thickness and OD are used for each particular gage location. The strain gage based strain is determined using the strain readings from each of the strain gages used during testing. Each strain gage produces three outputs; Strain in the hoop direction (ε1), strain in the axial direction (ε3), and strain in the 45° direction, (ε2), as shown in Figure 3.

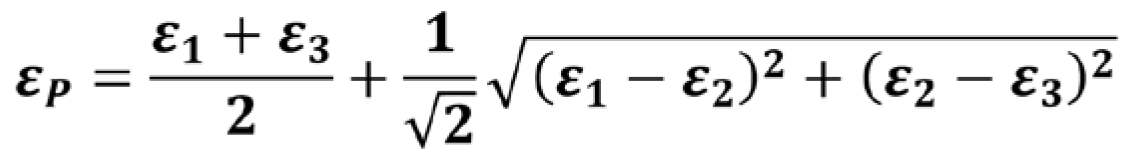

The strain measurement from each gage rosette direction is then used to calculate the maximum principal strains using Equation 2:

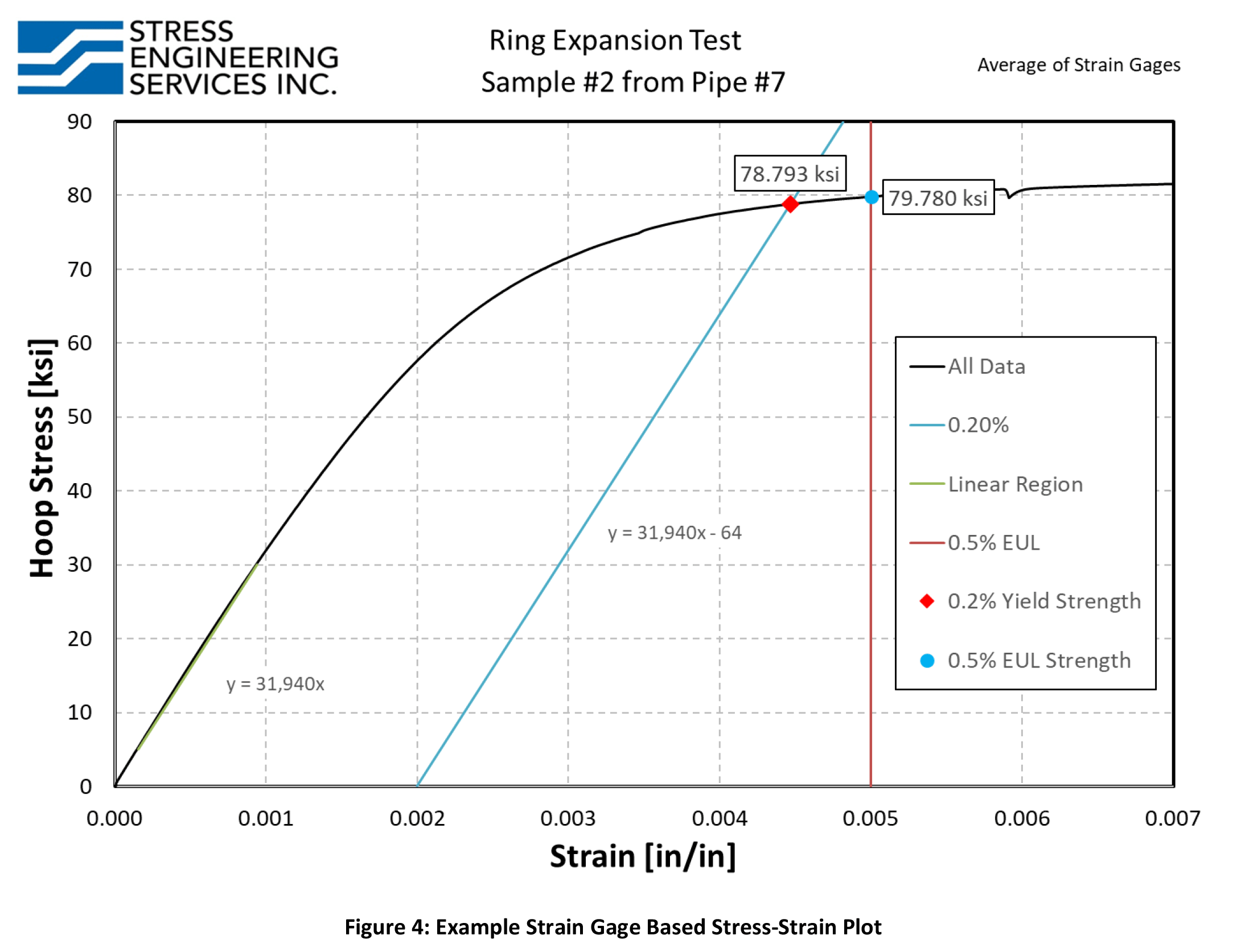

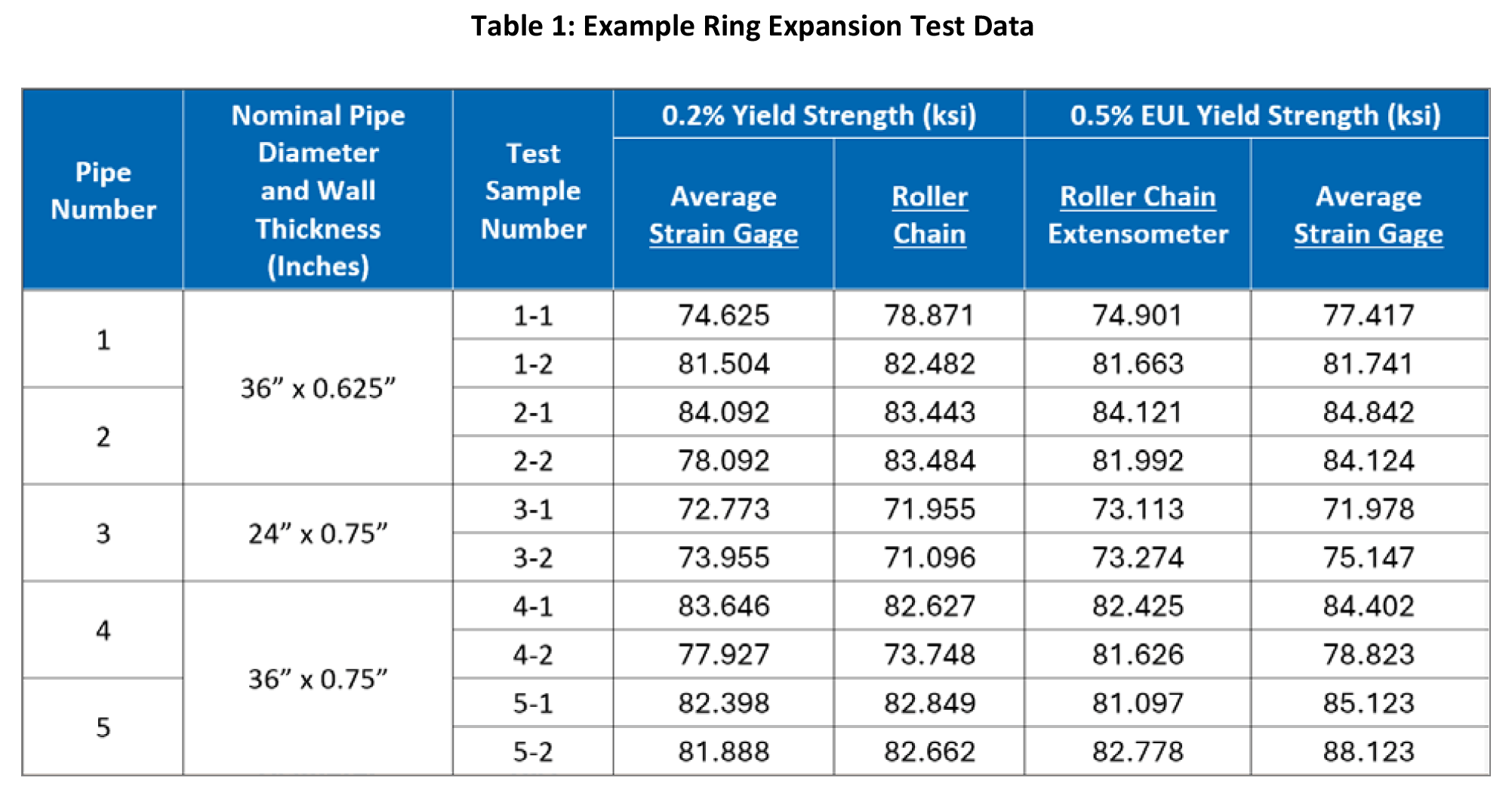

The maximum principal strains at all 4 gage locations are then averaged and used for the strain gage based Stress-Strain plots. An example plot is shown in Figure 4. In some tests, it is possible that one or more of the strain gages do not reach a 0.2% Offset or 0.5% EUL yield point. For these cases, only the strain gages that reached a yield point can be averaged.

Other Mechanical Tests — What They Measure (and Why Ring Expansion Is Better for Hoop Properties)

Tensile Specimen Testing (Round-Bar & Flat-Strap)

- What it is: A machined coupon (round or flat) is pulled in a universal test machine along its long axis. Specimens may be taken longitudinal or transverse to the pipe axis. The test data gives yield strength (often 0.2% offset or EUL), Ultimate Tensile Strength, elongation, and sometimes reduction of area.

- Where it shines: High-resolution stress–strain data, standardized gauge lengths, mill/weld procedure qualifications, comparison to historical datasets, and localized sampling of base metal, weld metal, or HAZ in the pipe axial direction.

- Where it falls short for hoop properties: Circumferentially oriented specimens are sometimes hard or impossible to machine from some pipe geometry. Transverse flat straps require flattening a curved wall, which introduces bending and alters stresses (Bauschinger effect). The load path is axial, not circumferential under internal pressure. The gauge length is a small distance, not the full circumference, so localized properties can bias results, making the test data not as representative of full pipe behavior.

Guided-Bend Testing

- What it is: A rectangular bend coupon (face, root, or side) is wrapped around a specified mandrel diameter to a target angle. It is a pass/fail ductility/soundness check for weld procedures and production welds.

- Where it falls short for hoop properties: The stress state is dominated by through-thickness bending with a strong strain gradient (high surface strain, low mid-thickness strain). It does not provide a stress-strain curve, or a pressure equivalent response.

Flattening Tests (Pipe/Ring Flattening)

- What it is: Sections of pipe are compressed between flat platens to a specified flattening distance. Commonly used to assess weld seam soundness (e.g., ERW) and detect laminations or brittleness; often with the seam at a prescribed orientation.

- Where it falls short for hoop properties: Flattening forces the wall through severe bending and ovalization, intentionally creating a worst-case strain field to expose seam defects. It disrupts the original curvature and residual stress state, so it cannot represent the pipe body’s pressure-driven hoop response.

Why Ring Expansion Is Better for Hoop Properties

- Correct loading mode: Ring expansion creates circumferential membrane tension under internal pressure—the same mode that governs pressure containment—rather than bending-dominated states.

- Geometry fidelity: The full circumference remains curved; no flattening means no reverse- bending/Bauschinger artifacts. The gauge length is the entire circumference, averaging material property and geometry variations.

- Lower scatter for yield strength: Eliminating coupon machining/flattening variability typically tightens distributions for transverse yield strength.

- Better linkage to burst. Programs comparing ring expansion testing with hydrostatic burst show correlated data; ring-based hoop yield strength is a more defensible input for integrity assessments.

It is important to know and understand the test method being used and what the results mean. Conventional coupon tensile tests can be used to establish ultimate tensile strength, total elongation, to map HAZ vs. weld metal, and to qualify procedures. Guided-bend/flattening test can be used to verify weld quality and seam ductility. Ring expansion testing is used when the design/assessment hinge on an accurate measurement of the pipe body’s hoop yield under pressure.

Ring expansion is the most direct way to measure hoop yield on the actual pipe geometry under internal pressure. It is recognized by API 5L and implemented via ASTM A370. Done correctly, it typically yields a truer, less scattered transverse yield strength and a cleaner link to burst behavior than flattened coupons.

Matt Sanders, PE – Principal and Program Director at Stress Aerospace and Defense

Matt serves on the Texas A&M Mechanical Engineering Department Industry Advisory Council and multiple national standards committees, including API and ASTM. He leads qualification engineering projects using advanced testing, materials science, instrumentation, and analysis for aerospace, defense, and energy applications. He holds B.S. and M.S. degrees in mechanical engineering from Texas A&M.

Leave a Comment Cancel reply

You must Register or Login to post a comment.