Welding Engineering

Welding and joining processes are used in virtually all materials systems. From glued joints in plastic to automated sub-arc welding of steel riser pipe, joints are a common location of failures. The materials, metallurgical, and welding engineers at Stress Engineering Services have...

Welding and joining processes are used in virtually all materials systems. From glued joints in plastic to automated sub-arc welding of steel riser pipe, joints are a common location of failures. The materials, metallurgical, and welding engineers at Stress Engineering Services have... read More....

0

17

May 2021

Polymers | Elastomers | Composites

Our materials engineering capabilities expands across a wide range of plastic and polymeric materials, elastomers, composites, and manufacturing processes. Equipped with state-of-the-art testing laboratories and specialized tools, our engineers and technicians can expertly identify...

Our materials engineering capabilities expands across a wide range of plastic and polymeric materials, elastomers, composites, and manufacturing processes. Equipped with state-of-the-art testing laboratories and specialized tools, our engineers and technicians can expertly identify... read More....

0

17

May 2021

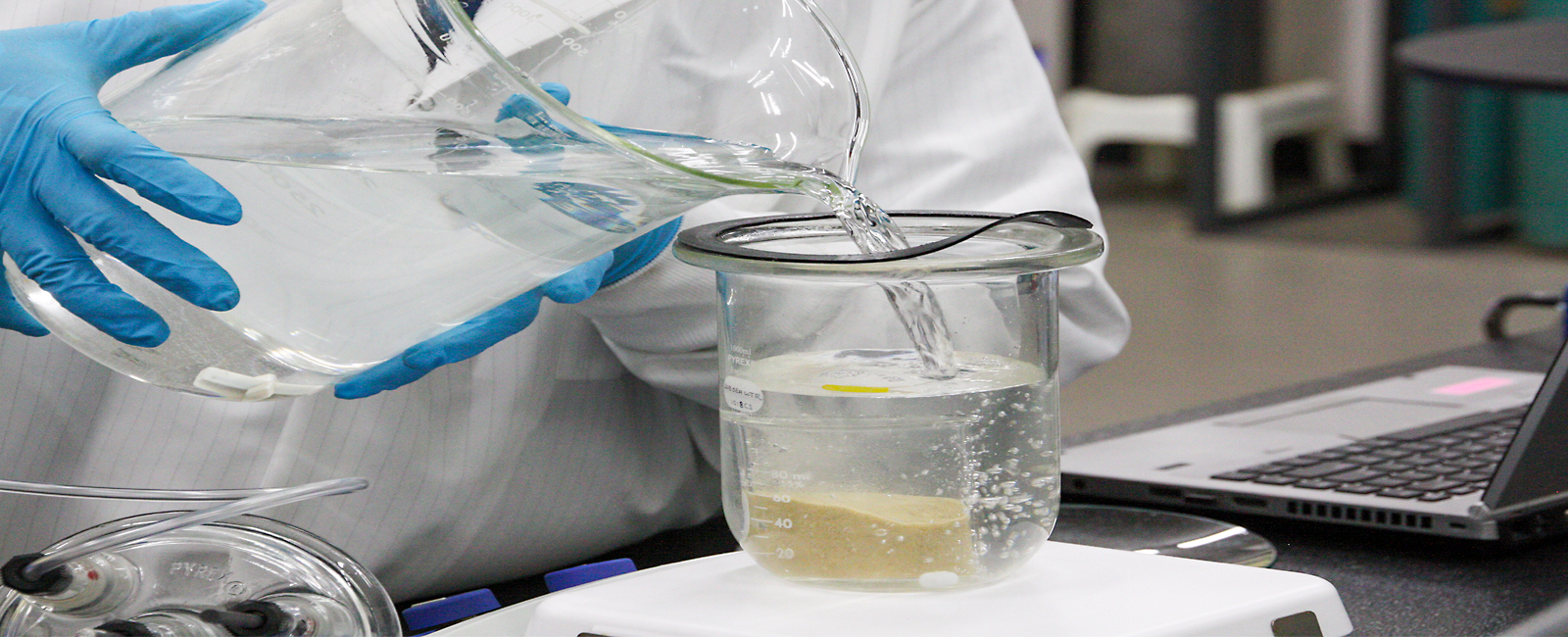

Metallurgical Laboratory Services

Stress Engineering Services offers full-service, metallurgical laboratory services in our Houston, Cincinnati, and Calgary offices. Our materials testing laboratories are equipped to provide a variety of analytical and testing services from failure analysis to on-site evaluation,...

Stress Engineering Services offers full-service, metallurgical laboratory services in our Houston, Cincinnati, and Calgary offices. Our materials testing laboratories are equipped to provide a variety of analytical and testing services from failure analysis to on-site evaluation,... read More....

0

17

May 2021

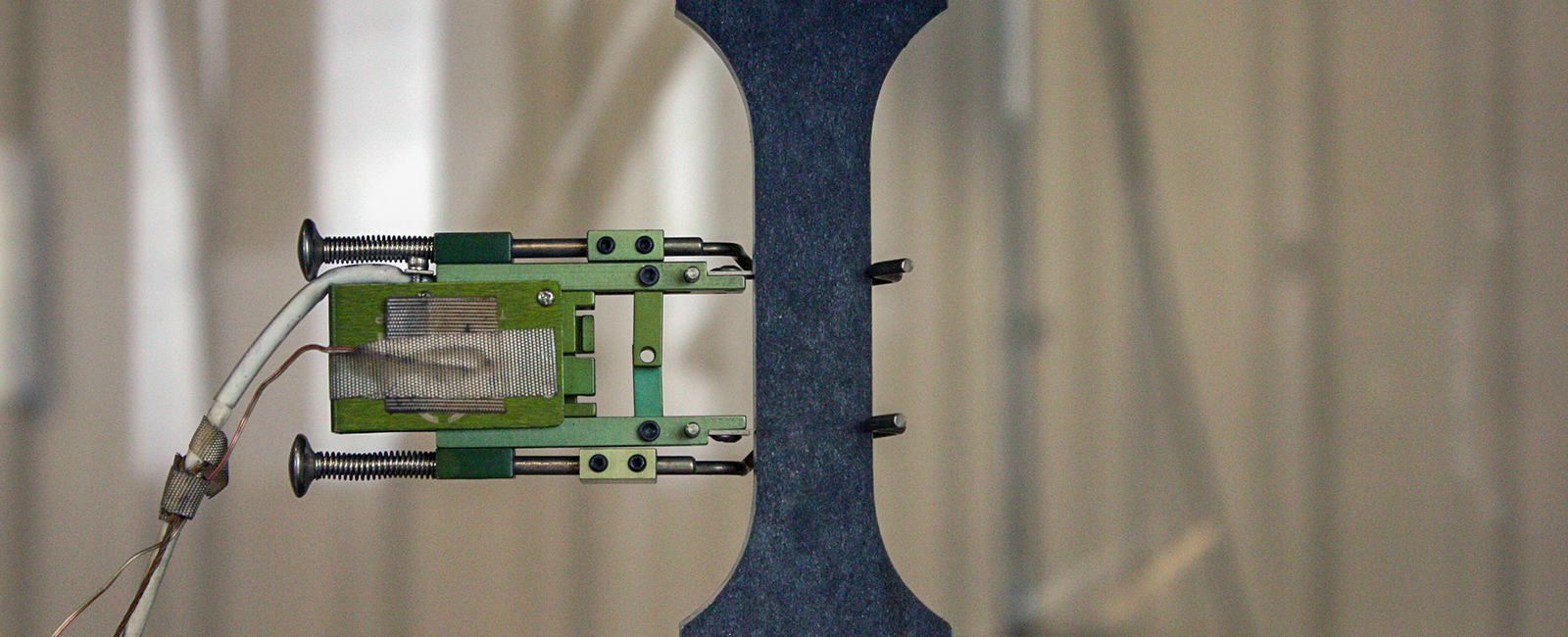

Materials Testing

The foundation of our materials engineering and metallurgy services is our comprehensive, laboratory-based material testing and characterization capabilities. Our independent materials testing laboratories are equipped with state-of-the-art equipment for a wide range of...

The foundation of our materials engineering and metallurgy services is our comprehensive, laboratory-based material testing and characterization capabilities. Our independent materials testing laboratories are equipped with state-of-the-art equipment for a wide range of... read More....

0

17

May 2021

Materials Selection & Characterization

At Stress Engineering Services, we focus on assisting clients with material selection processes to ensure that the most reliable and economic materials are chosen for a particular application. Our engineers use their diverse, in-depth experience and an assortment of testing and...

At Stress Engineering Services, we focus on assisting clients with material selection processes to ensure that the most reliable and economic materials are chosen for a particular application. Our engineers use their diverse, in-depth experience and an assortment of testing and... read More....

0

17

May 2021

Field Inspection and Testing

We are a leading provider of inspecting and non-destructive testing of engineered components and structures. Our multi-disciplinary team of skilled engineers and technicians regularly perform in-situ assessments and non-destructive testing to identify the root causes of failures and...

We are a leading provider of inspecting and non-destructive testing of engineered components and structures. Our multi-disciplinary team of skilled engineers and technicians regularly perform in-situ assessments and non-destructive testing to identify the root causes of failures and... read More....

0

17

May 2021

Failure Analysis

A failure can be the result of a manufacturing defect, maintenance practices, operating parameters, or even design related. More importantly, identifying the root cause of the failure makes it possible to develop a deliberate plan for corrective action and avoid another failure in...

A failure can be the result of a manufacturing defect, maintenance practices, operating parameters, or even design related. More importantly, identifying the root cause of the failure makes it possible to develop a deliberate plan for corrective action and avoid another failure in... read More....

0

17

May 2021

Corrosion Engineering

At Stress Engineering Services, we use our extensive training, field experience, and advanced analysis tools to identify and help control modes of corrosion and environmental degradation of materials that can lead to component or system-wide failures. We conduct a variety of...

At Stress Engineering Services, we use our extensive training, field experience, and advanced analysis tools to identify and help control modes of corrosion and environmental degradation of materials that can lead to component or system-wide failures. We conduct a variety of... read More....

0

17

May 2021

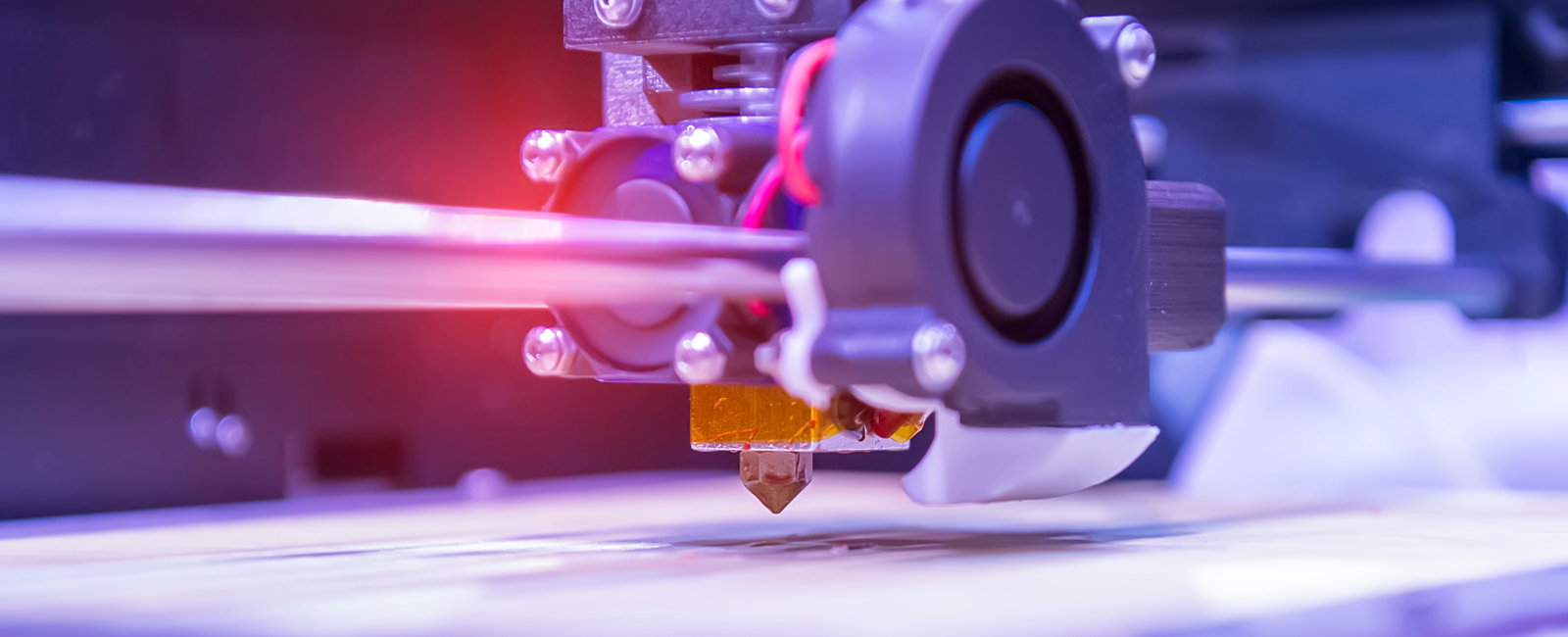

Additive Manufacturing

Leveraging advanced engineering simulation and testing methods with the power of artificial intelligence for efficient robust qualifications. What is Additive Manufacturing? Additive Manufacturing allows for the swift and efficient production of parts straight from 3D CAD data....

Leveraging advanced engineering simulation and testing methods with the power of artificial intelligence for efficient robust qualifications. What is Additive Manufacturing? Additive Manufacturing allows for the swift and efficient production of parts straight from 3D CAD data.... read More....

0

17

May 2021