Visualizing Vibration with VVA

Video Vibration Amplification (VVA) is a powerful tool to help visualize and understand vibration. It is easy to tell that the equipment is vibrating, but it is much more difficult to understand how. That is where VVA can make a big difference. It uses special algorithms to amplify motion at the sub-pixel level that is recorded with high-speed cameras. This allows for the ability to create videos that exaggerate the motion to make it visible for the human eye, making the vibration much easier to understand.

What is VVA? It is a motion amplification technology that enhances subtle motions in video, making invisible vibrations visible and measurable. It is a non-contact form of vibration analysis that uses video pixels as virtual sensors for high resolution yet non-invasive vibration measurement. It has industrial applications in that it can improve diagnostics and monitoring by visualizing hidden motion.

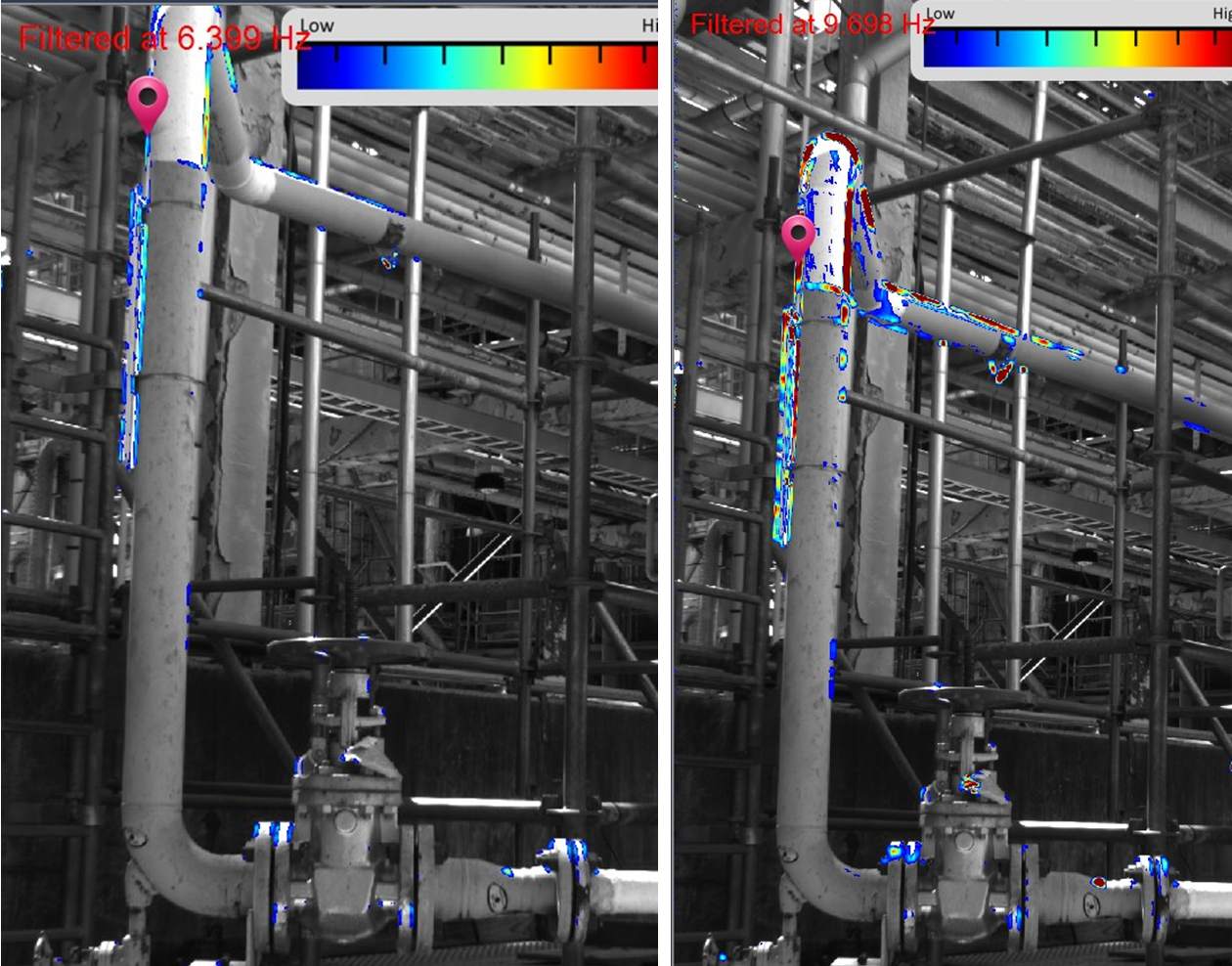

VVA works by using a high-resolution camera to record video of machines, equipment, and supporting structures to observe subtle vibrations. It then uses motion detection algorithms to analyze pixel changes to detect sub-pixel motions that are otherwise invisible to the naked eye. It then amplifies the vibration to reveal the patterns based on user screening criteria.

Some of the key features are:

- Measurement is Non-contact

- Sub-Micron Sensitivity

- Quick Setup and Data Acquisition

- Intuitive Video-based Results

Some limitations are:

- Limited Viewpoints

- Dependence on Lighting and Stability

- Requires Post-processing

- Syncing Multi-directional Data

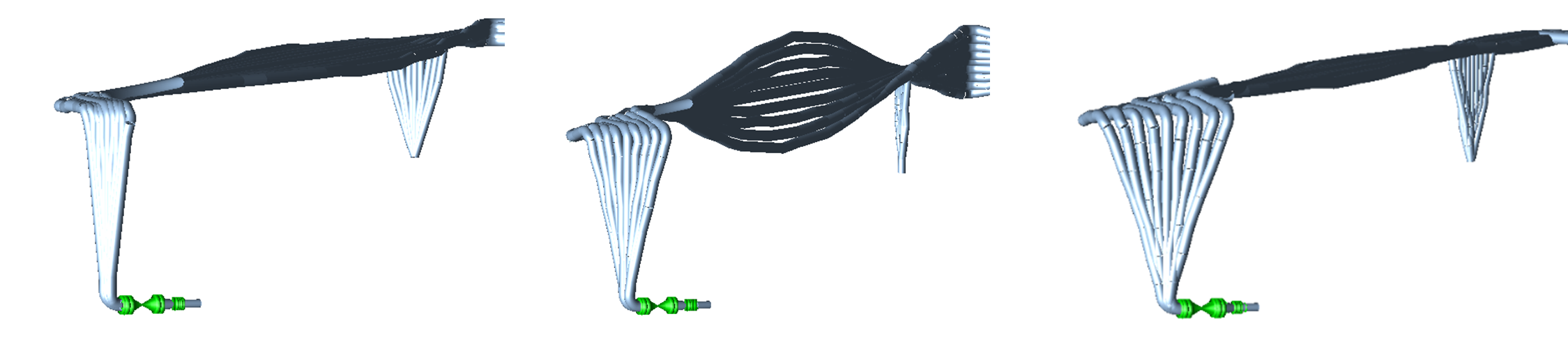

This can be an especially powerful tool when combined with analytical models. This capability is not new, but it is more accessible now than ever before. This helps match the analytical model to real-world vibrations, providing confidence in the model and the predicted solutions.

Here, the technology shines in visualizing mode shapes. It helps determine if the motion is bending in a fundamental mode or a more complex motion. It can differentiate between different frequencies and modes and filter out motion to visualize them independently, so even if the vibration is visible or can be felt, it can help determine if it is one mode or multiple. It can show how the vessel walls are deflecting with the motion of the piping at the nozzle connection.

This is a transformative tool that can help troubleshoot vibrating equipment and provide insight into vibration issues. It doesn’t eliminate the need for additional sensors and more in-depth analysis, but can certainly help make sure the focus is in the right areas. It has been used effectively in diagnosing piping vibration, pumps, fans, turbines, and structural support issues.

Ryan Hopman, P.E. – Associate at Stress Engineering Services

Ryan is a vibration engineer who has worked in the integrity assessment & design services in both the aerospace & petrochemical industries. He has a background in mechanical engineering with an emphasis in vibration, with 15 years of experience with hands-on vibration testing, measurement & analysis. Ryan has tackled vibration problems from data collection to stress analysis & remaining life for a wide variety of fixed equipment types & applications.

He has a master’s degree in mechanical engineering from the Georgia Institute of Technology, is a member of ASME, and is a registered professional engineer in the state of Louisiana.

Leave a Comment

You must Register or Login to post a comment.