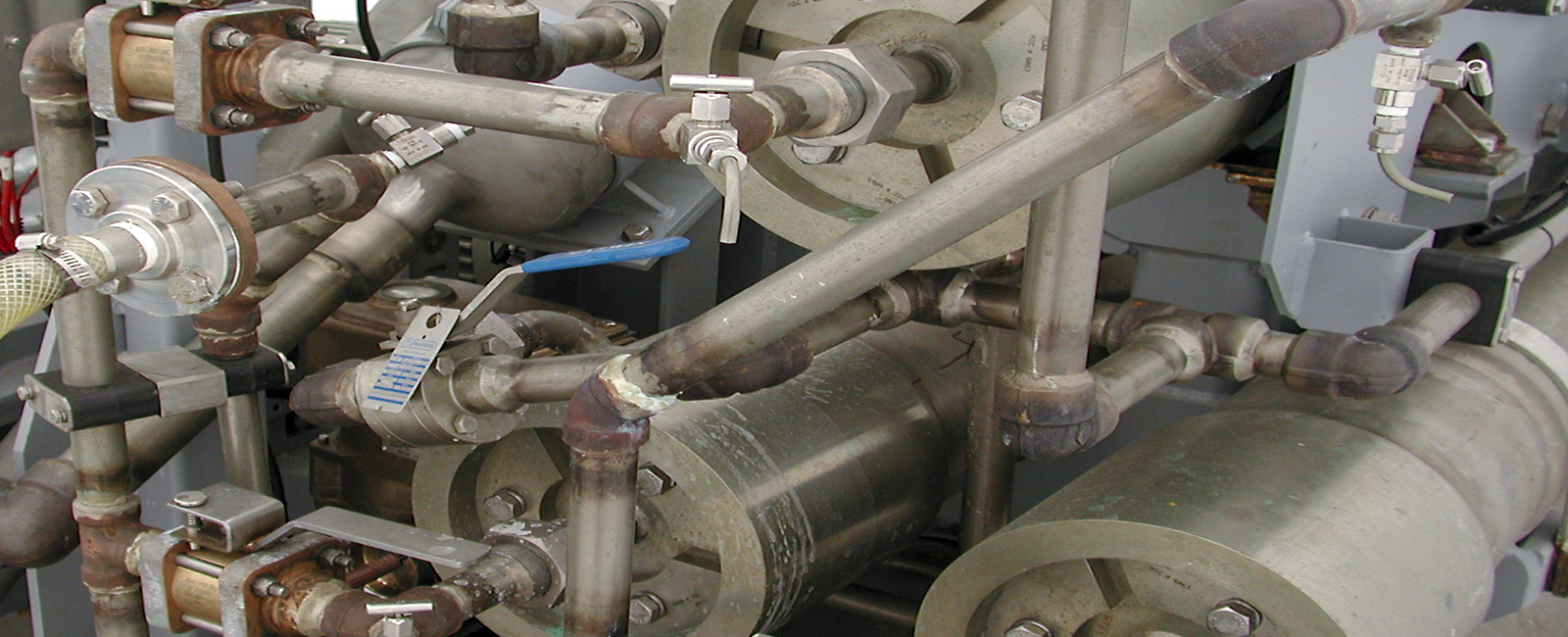

Equipment Vibration Monitoring

Field Vibration Surveys – Portable Data Acquisition Most field vibration troubleshooting starts with basic data collection via portable, hand-held signal analyzers that are easily moved around multiple locations in the vicinity of a vibration problem. Even complicated...

Field Vibration Surveys – Portable Data Acquisition Most field vibration troubleshooting starts with basic data collection via portable, hand-held signal analyzers that are easily moved around multiple locations in the vicinity of a vibration problem. Even complicated... read More....

0

17

May 2021

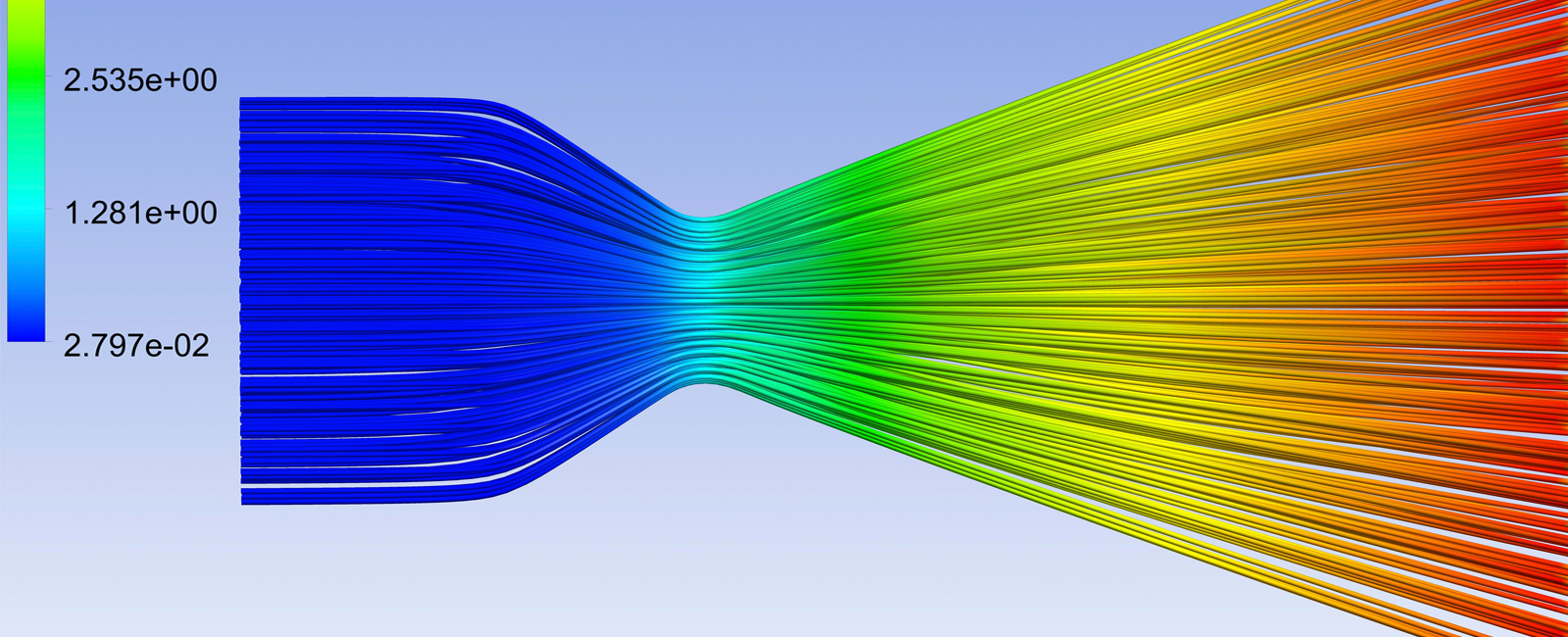

Computational Fluid Dynamics

Stress Engineering Services is an industry leader in the application of computational fluid dynamics (CFD) methods. The ‘virtual prototyping’ provided by these methods allows engineers to test a wide range of alternative designs quickly and cost-effectively. CFD implementation...

Stress Engineering Services is an industry leader in the application of computational fluid dynamics (CFD) methods. The ‘virtual prototyping’ provided by these methods allows engineers to test a wide range of alternative designs quickly and cost-effectively. CFD implementation... read More....

0

17

May 2021

Vulnerability Assessments

Process Unit Corrosion Vulnerability Assessment Corrosion reviews of process units are routinely performed as part of the mechanical integrity program for pressure vessels and piping systems. This essentially consists of the following tasks: Develop an inventory of the...

Process Unit Corrosion Vulnerability Assessment Corrosion reviews of process units are routinely performed as part of the mechanical integrity program for pressure vessels and piping systems. This essentially consists of the following tasks: Develop an inventory of the... read More....

0

17

May 2021

Verification & Validation

A verification and validation process confirms that specified requirements for equipment, services, and systems are met for proper functioning and their intended purpose. Independently, verification is usually an internal process that evaluates if a machine or system satisfies any...

A verification and validation process confirms that specified requirements for equipment, services, and systems are met for proper functioning and their intended purpose. Independently, verification is usually an internal process that evaluates if a machine or system satisfies any... read More....

0

17

May 2021

Turnaround Support

Improving Turnarounds Through Detailed Engineering The ability to quickly evaluate equipment is critical for minimizing costs during Turnarounds. There is a wide range of opportunities for cost savings that a company can achieve during a Turnaround. In typical Turnaround...

Improving Turnarounds Through Detailed Engineering The ability to quickly evaluate equipment is critical for minimizing costs during Turnarounds. There is a wide range of opportunities for cost savings that a company can achieve during a Turnaround. In typical Turnaround... read More....

0

17

May 2021

Process Engineering

Our Process Technology team is comprised of Subject Matter Experts in mechanical, civil, electrical, metallurgical, materials, water chemistry, theoretical and applied mechanics. More importantly, they provide “Actionable” engineering solutions to improve plant operations. ...

Our Process Technology team is comprised of Subject Matter Experts in mechanical, civil, electrical, metallurgical, materials, water chemistry, theoretical and applied mechanics. More importantly, they provide “Actionable” engineering solutions to improve plant operations. ... read More....

0

17

May 2021

Mechanical Integrity

Critical process equipment must be designed, installed, operated, and maintained properly to ensure dependable and safe operation—ultimately leading to a sound and successful business enterprise. Fixed Equipment Mechanical Integrity manages the programs and activities in place to...

Critical process equipment must be designed, installed, operated, and maintained properly to ensure dependable and safe operation—ultimately leading to a sound and successful business enterprise. Fixed Equipment Mechanical Integrity manages the programs and activities in place to... read More....

0

17

May 2021

High Temperature Hydrogen Attack (HTHA) Assessments

Improved Models for Life Assessment, Inspections, and Repair-Replace Decisions Within the refinery and chemicals industries, high temperature hydrogen attack (HTHA) continues to be a process-safety issue. Stress Engineering Services (SES) has observed a growing industry need for...

Improved Models for Life Assessment, Inspections, and Repair-Replace Decisions Within the refinery and chemicals industries, high temperature hydrogen attack (HTHA) continues to be a process-safety issue. Stress Engineering Services (SES) has observed a growing industry need for... read More....

0

17

May 2021

Health Monitoring Systems

Implementing an Equipment Health Monitoring System (EHMS) in a coker facility can significantly help refinery managers and coker-unit supervisors to better identify, track, and plan remediation measures to address coker vessel cracks, bulges, repairs, or to change parameters for...

Implementing an Equipment Health Monitoring System (EHMS) in a coker facility can significantly help refinery managers and coker-unit supervisors to better identify, track, and plan remediation measures to address coker vessel cracks, bulges, repairs, or to change parameters for... read More....

0

17

May 2021