17

May 2021

Acoustic Emission Testing

Stress Engineering Services is a world-renowned authority in Acoustic Emission Testing (AET). Our expertise extends beyond the mere ability to conduct AET; we use our immense capabilities and experience to fully analyze AET results to determine how they impact fitness for...

Stress Engineering Services is a world-renowned authority in Acoustic Emission Testing (AET). Our expertise extends beyond the mere ability to conduct AET; we use our immense capabilities and experience to fully analyze AET results to determine how they impact fitness for... read More....

0

17

May 2021

API 579 Fitness-for-Service Assessments

Fitness-For-Service (FFS) assessments, according to the American Petroleum Institute (API), are “quantitative engineering evaluations that are performed to demonstrate the structural integrity of an in-service component containing a flaw or damage.” Publication of API RP-579...

Fitness-For-Service (FFS) assessments, according to the American Petroleum Institute (API), are “quantitative engineering evaluations that are performed to demonstrate the structural integrity of an in-service component containing a flaw or damage.” Publication of API RP-579... read More....

0

17

May 2021

Valves

Valve failures have contributed to some of the industry’s most catastrophic incidents. Since valves control the flow and pressure of piping system contents, mechanical integrity is vital. Valve types include ball, butterfly, check, diaphragm, gate, globe, plug, and slide valves,...

Valve failures have contributed to some of the industry’s most catastrophic incidents. Since valves control the flow and pressure of piping system contents, mechanical integrity is vital. Valve types include ball, butterfly, check, diaphragm, gate, globe, plug, and slide valves,... read More....

0

17

May 2021

Storage Tanks

Aboveground Storage Tanks (ASTs) are prominent plant components used for temporary storage of liquid or gas substances such as water, chemical products, and crude oil. Though tanks are comparatively simple assets, their individual parts all require a specific and intimate...

Aboveground Storage Tanks (ASTs) are prominent plant components used for temporary storage of liquid or gas substances such as water, chemical products, and crude oil. Though tanks are comparatively simple assets, their individual parts all require a specific and intimate... read More....

0

17

May 2021

Steam Methane Reformers (SMRs)

Steam Methane Reforming is the most extensively used process of hydrogen production in the United States. Typical steam methane reformers (SMRs) house 200 to 400 reformer tubes – also known as catalyst tubes – where the initial reactions occur to generate hydrogen from methane in...

Steam Methane Reforming is the most extensively used process of hydrogen production in the United States. Typical steam methane reformers (SMRs) house 200 to 400 reformer tubes – also known as catalyst tubes – where the initial reactions occur to generate hydrogen from methane in... read More....

0

17

May 2021

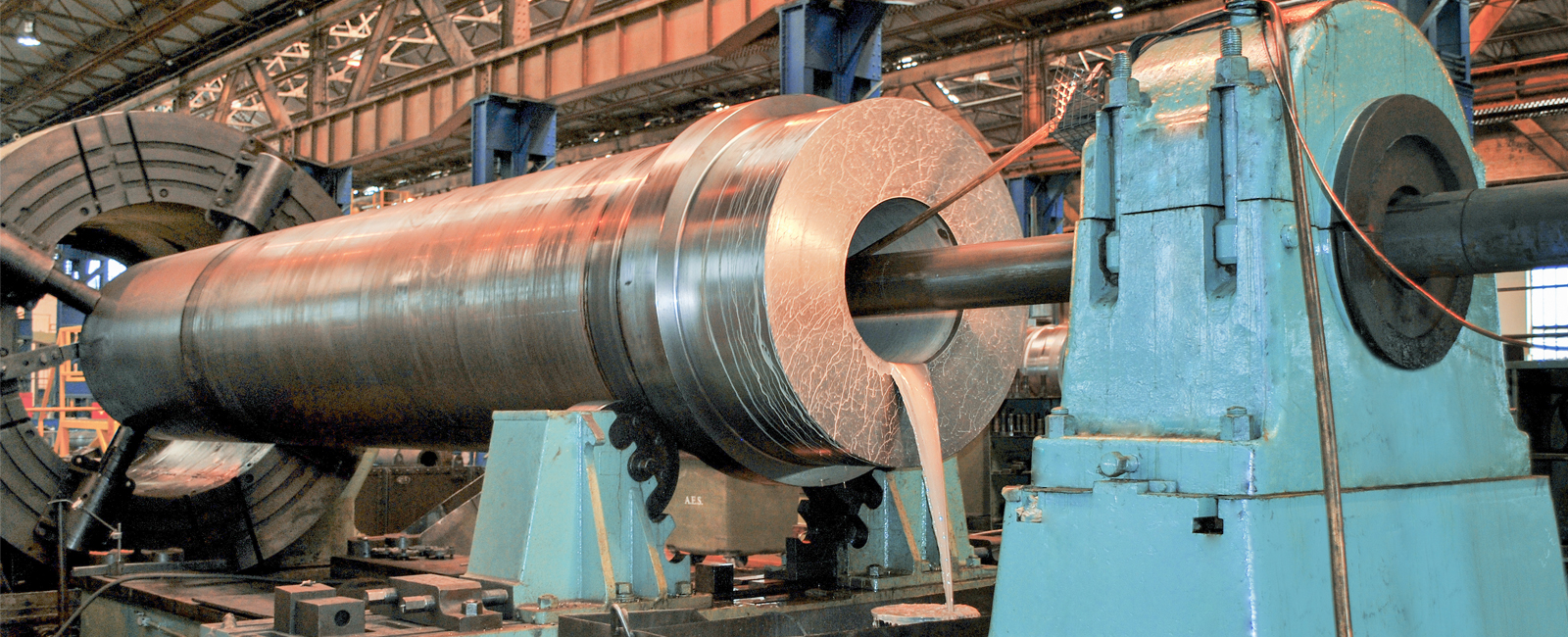

Pressure Vessels & Heat Exchangers

Manufacturing, Evaluating, and Re-rating Pressure Vessels Stress Engineering Services, Inc. is a certified ASME Boiler and Pressure Vessel Code (BPVC) Code Stamp holder. We design, manufacture, and install pressure vessels around the world, and can issue Certificates of...

Manufacturing, Evaluating, and Re-rating Pressure Vessels Stress Engineering Services, Inc. is a certified ASME Boiler and Pressure Vessel Code (BPVC) Code Stamp holder. We design, manufacture, and install pressure vessels around the world, and can issue Certificates of... read More....

0

17

May 2021

Piping Systems

A Complete Approach to Ensure Piping System Integrity Stress Engineering Services, Inc. offers an all-encompassing approach to piping system integrity. The program comprises all necessary elements: a review of the design, a walkdown, analyses, inspections, evaluations, and...

A Complete Approach to Ensure Piping System Integrity Stress Engineering Services, Inc. offers an all-encompassing approach to piping system integrity. The program comprises all necessary elements: a review of the design, a walkdown, analyses, inspections, evaluations, and... read More....

0

17

May 2021

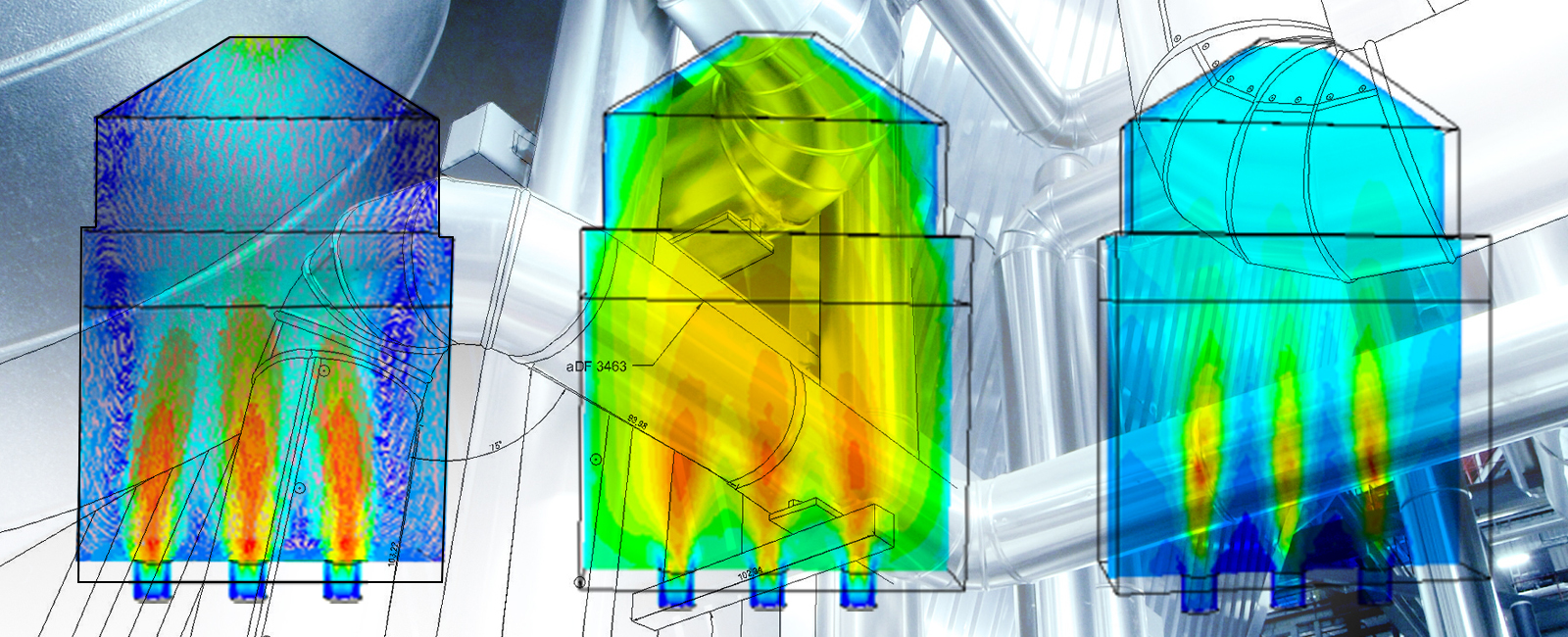

Fired Heaters / Boilers

Fired heaters and boilers are essential yet volatile components of downstream plant operations. Given the combustible processes and complex pieces of equipment involved in heating gases and liquids, fired heaters are innately prone to heightened safety, reliability, and economic...

Fired heaters and boilers are essential yet volatile components of downstream plant operations. Given the combustible processes and complex pieces of equipment involved in heating gases and liquids, fired heaters are innately prone to heightened safety, reliability, and economic... read More....

0

17

May 2021

...

...