Pallet Packaging Solutions

PalletDAQ®

Transportation Data Logging

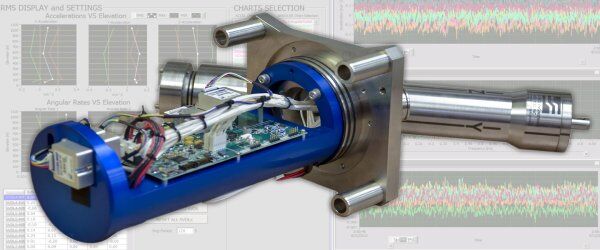

Our PalletDAQ® services involve the use of our proprietary, self-contained data acquisition system that documents the performance of unit loads, cases and individual packages during handling and transport. With our PalletDAQ services, we are able to monitor and record multiple channels of mixed sensors for extended periods of time.

Designing packaging systems for stability or cost savings requires knowing about the specific distribution system, and how both primary and secondary packaging behaves in that environment. This is particularly true with caseless trays.

Our PalletDAQ services work on a standard 40” x 48” pallet footprint. Hardware and batteries are protected inside the rugged metal enclosures, and the system can be handled in the supply chain like any other pallet.

In addition, our PalletDAQ services are designed so that you can quickly and easily download destination data. Typical measurements include load, pressure, acceleration, temperature, humidity, inclination, and displacement, but we can configure the system to record other data as required.

PalletSled®

Stretch Wrapped Unit Load Stability

Manufacturers of products like rolled paper goods, salted snacks, food, beverages, liquid laundry, and beauty care products, to name a few, are under significant pressure to deliver packaging systems with improved stability and sustainability while reducing costs, but having sufficiently adequate primary, secondary and tertiary packaging to survive distribution. As a result of many interacting variables, many of our clients are encountering an increased frequency of product rejection as a result of unit load collapse in distribution. At an alarming rate, trailer loads of products are being rejected because of leaning, collapse, or damaged unit loads.

The remediation fire drill usually begins with numerous time consuming and expensive ship tests where stretch wrap materials and stretch wrapper settings are varied. This approach, however, usually generates ambiguous results with little or no quantitative data to provide confidence that a solution has been identified. Also, because of the time and expense, the number of material and process variables that are included in the testing is very limited.

Utilizing years of physics-based analysis and testing of unit load-based packaging systems, we developed and now offer a testing service for portable units. This service, known as PalletSled® can be used at our clients’ sites, in very close proximity to the stretch wrapper, to quantitatively evaluate and rank the performance of possible stretch wrap and palletizer solutions in real time without interfering with the plant production, including:

- Stretch wrap tension variation

- Wrap pattern

- Number of wraps

- Case stack patterns

- Stretch wrap film material properties

- Stretch wrap gauge (thickness)

- Unit load overhang and under-hang

- Palletizer stacking variations (case gaps, layer compression load, unit load centerness, layer-to-lay off-set)

Our PalletSled services make it possible to perform designed experiments (DOE) to identify the best possible solution for a given set of unit load variables and constraints at the only location where a valid test can be performed – adjacent to your packing line!