Video

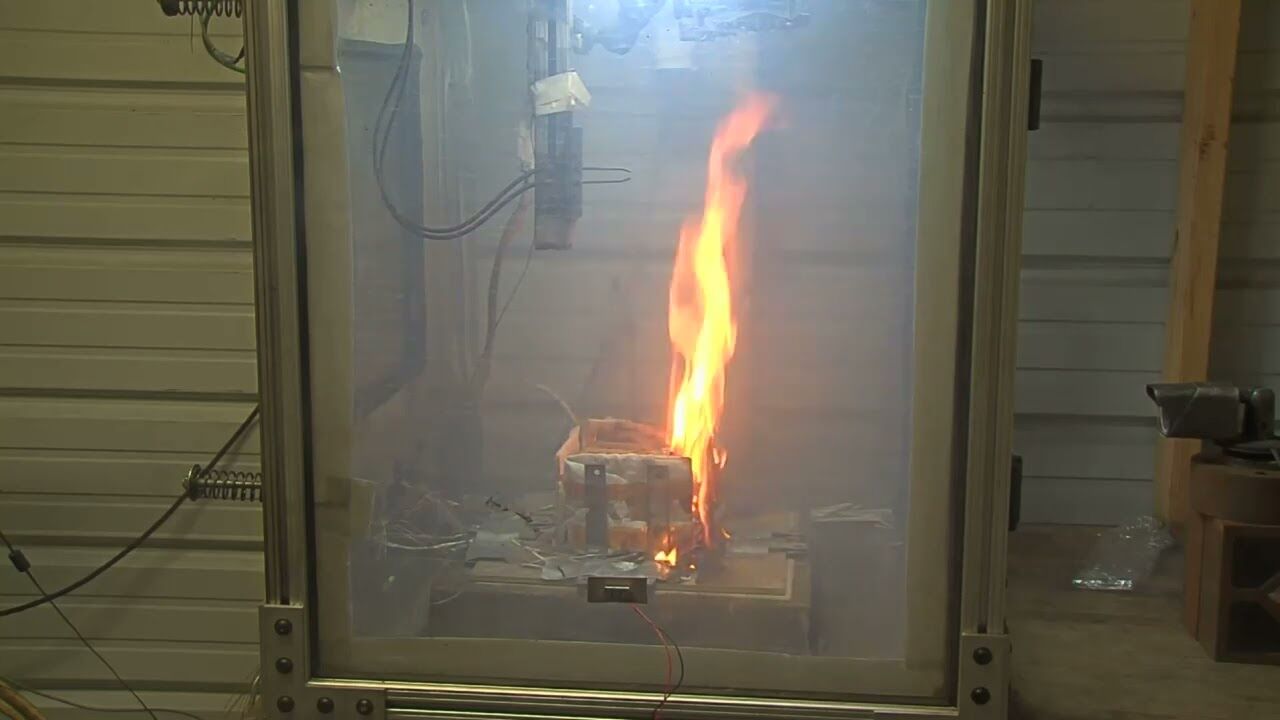

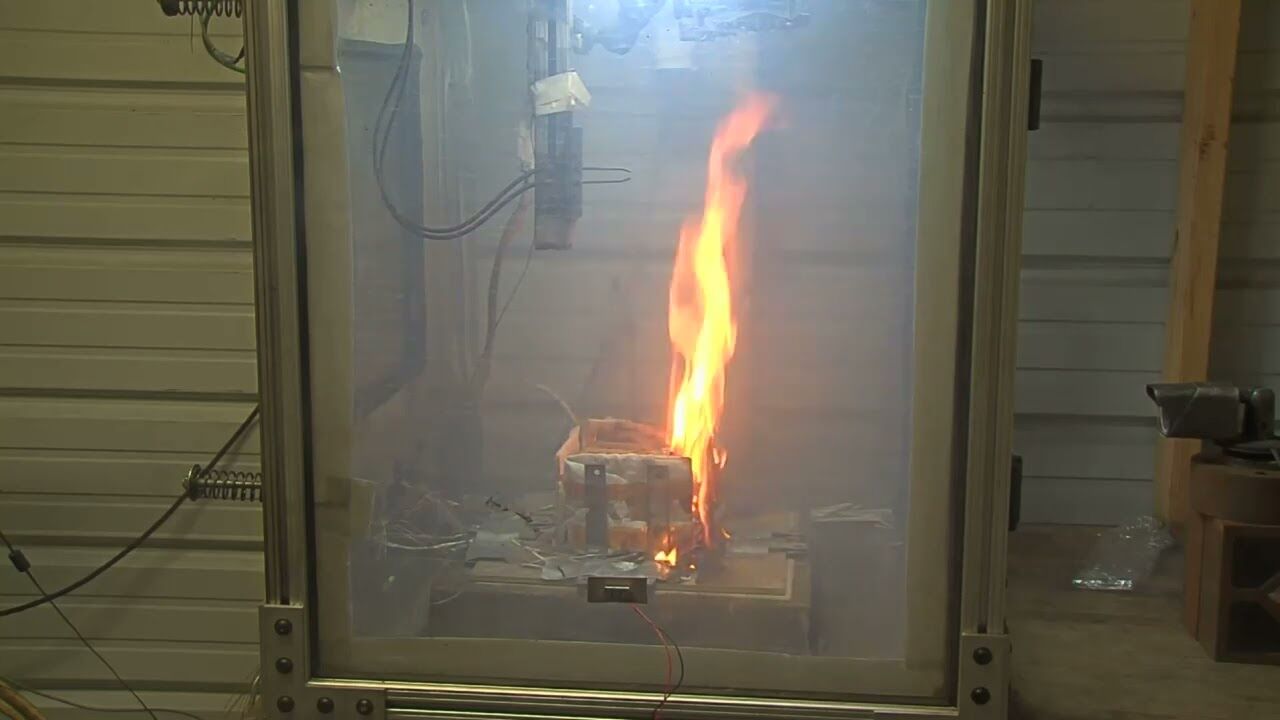

Battery Packaging Performance Test

Stress Engineering Services, Inc. (SES) offers battery safety and performance testing to various industry standards and has facilitated the development of standards by which batteries are tested. We provide expert battery testing services for clients across several applications and industries, including: Aerospace; Automotive; Grid Storage; Transportation; Aviation; Oil and Gas; Maritime; Medical; and Consumer Electronics.

Our Battery Testing Services dig deep into the complex electrochemical/thermal system that constitutes a Lithium-ion Battery to provide answers to critical questions shared by both battery engineers and end users alike, including:

Thermal runaway propagation testing, containment testing, standards development testing, cycle life and performance testing and fire exposure resistance testing are all performed at our Testing Facility in Waller, Texas. This state-of-the-art test facility houses a wide array of equipment used to characterize the cells electrically, along with various chambers for environmental control, abuse testing, external fire testing, and gas analysis.

Video

Battery Packaging Performance Test

In addition to testing to various industry standards, we are engaged in several unique battery safety testing programs developed in collaboration with our clients including:

Our battery testing capabilities provide our clients with the assurance that their battery systems meet and exceed safety and performance requirements before installation and commissioning potentially saving millions of dollars in recall or redesign costs in the process. Our unique capabilities include:

If you would like more information on Stress Engineering Services, please call us at 281.955.2900, or complete the following form and one of our representatives contact you shortly. For a complete listing of contact information, visit our Locations page.

"*" indicates required fields