Condition Based Maintenance for Drilling Risers

Award Winning Technology!

2019 OTC Spotlight on New Technology® Award

As the critical conduit between the drilling rig and the well system, the drilling riser on a mobile operating drilling unit (MODU) is inspected for flaws every five years. The logistically complex process of physically transporting components for inspection by water and land is both costly and time-consuming.

At Stress Engineering Services, we use advanced laser-based measurement for the inspection of oilfield equipment and pipe/tubing, to implement a new standard process for collecting critical riser data. Our aim is to mitigate the costs and time associated with essential MODU drilling riser inspections, by empowering operators to:

- Reliably determine the condition of drilling riser joints

- Consistently predict when vital components will require service

- Accurately assess remaining component life

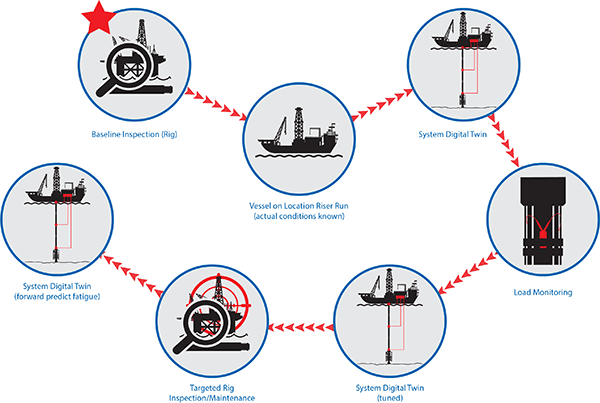

This approach utilizes a life cycle condition based monitoring (CBM), maintenance and inspection system that can be deployed on the MODU, enabling resources to be deployed only when necessary, instead of on a calendar interval.

How it works

The system determines stress and fatigue at any location in a riser system/wellhead/conductor casing with vibration sensors and data acquisition electronics housed in a Subsea Vibration Data Logger (SVDL). The data is processed using our state-of-the-art patented technology, designed to provide the drilling crew with critical, actionable information.

After the drilling riser joints have been recovered to the surface, the BEMIS™ (Bore Erosion Measurement and Inspection System) tool is used to inspect them. This data is collected while the riser is on the deck and eight joints can be inspected in one day, with the field results being available at the site, and a final report following in a week. BEMIS™ is a product developed by Laser Techniques Company LLC, and is the only system that accurately measures and maps the ID of pipe/tubing. This advanced level of inspection is designed to benefit those with a stake in identifying and managing risks and the deterioration of their tubular assets.

This ABS certified process delivers extensive and precisely compiled data, enabling the user to build a powerful picture to better understand their riser damage and wear rates.

A valuable report

The system delivers extensive and precisely compiled data, enabling the user to build a powerful picture to better understand their riser damage and wear rates.

The report provides the operator with vital knowledge:

- Current condition of the riser – if it is fit to return to service

- Extent and causes of any damage

- Effective determination of remaining life of riser

The report also includes a damage signature, noting the cause of the suspected damage (erosion, corrosion, mechanical damage or an irregularity from manufacturing).

Condition Based Maintenance for Drilling Risers Video

Additional Information:

![]() Life Cycle Condition Based Monitoring (CBM) and Maintenance

Life Cycle Condition Based Monitoring (CBM) and Maintenance