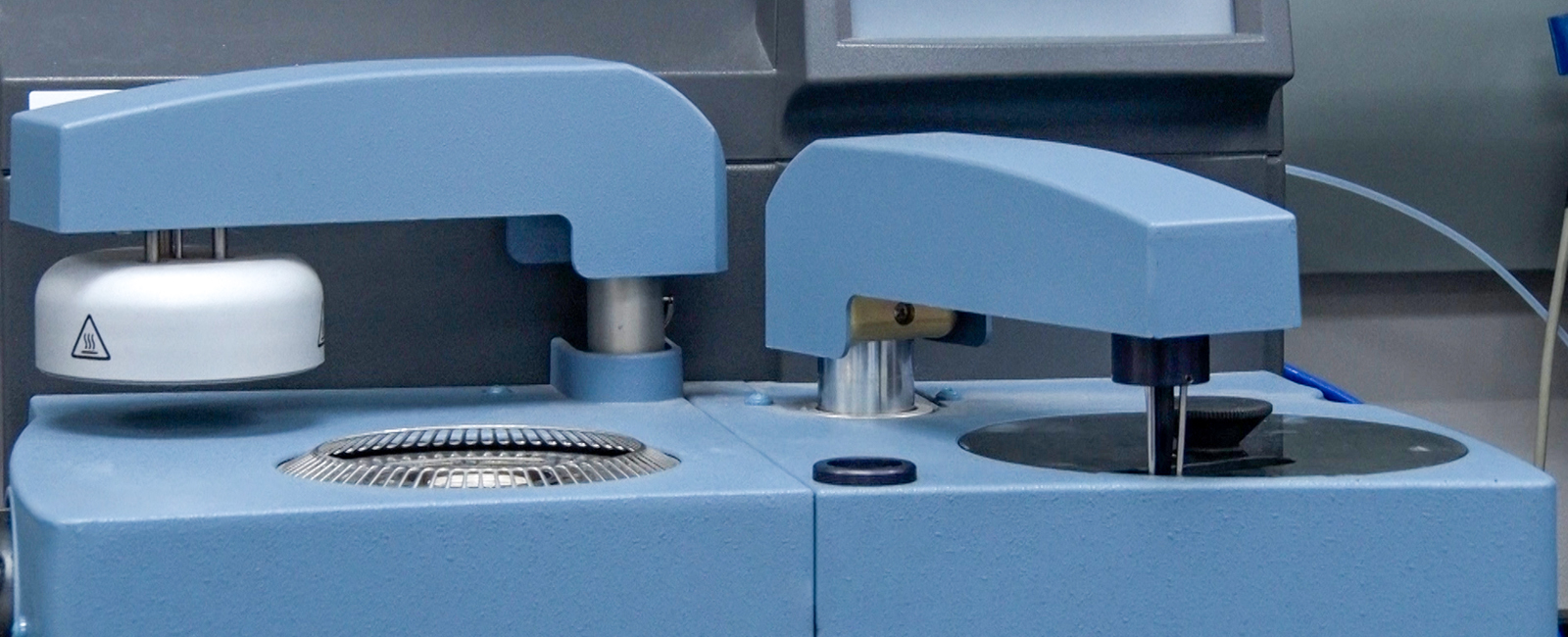

Differential Scanning Calorimetry

Stress Engineering Services provides Differential Scanning Calorimetry (DSC) for thermal analysis of polymers, elastomers, polymer based composites and liquids to support a variety of industrial market sectors and functions. DSC can be used to determine the effect of thermal...

Stress Engineering Services provides Differential Scanning Calorimetry (DSC) for thermal analysis of polymers, elastomers, polymer based composites and liquids to support a variety of industrial market sectors and functions. DSC can be used to determine the effect of thermal... read More....

0

17

May 2021

Accelerated Aging Testing

Utilizing our technical expertise in predictive analysis and accelerated aging testing methodologies, we have developed an approach that enables predicting long-term product life from relatively short-term test data. We use elements such as weathering, temperature, humidity, UV...

Utilizing our technical expertise in predictive analysis and accelerated aging testing methodologies, we have developed an approach that enables predicting long-term product life from relatively short-term test data. We use elements such as weathering, temperature, humidity, UV... read More....

0

17

May 2021

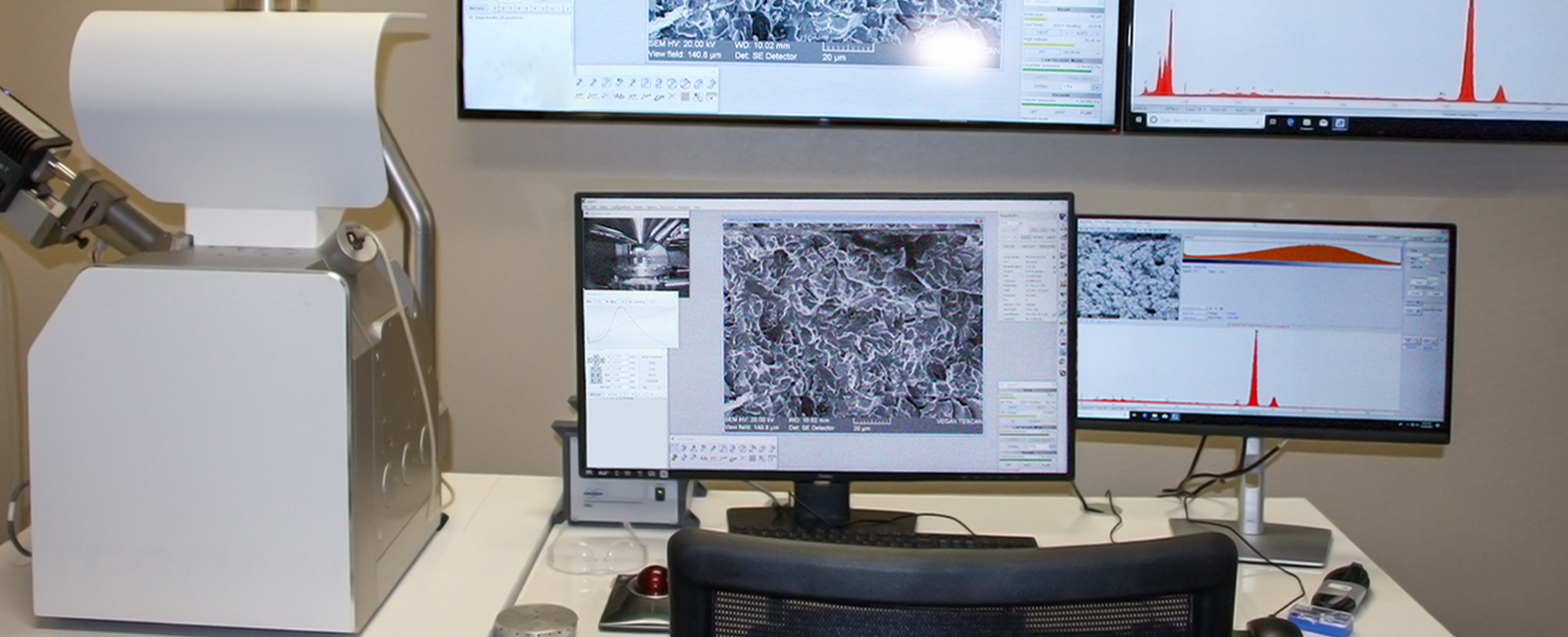

Scanning Electron Microscopy

A scanning electron microscope (SEM) uses a focused beam of electrons as the illumination source which is scanned or rastered over the surface of a sample to generate an image. The shorter wavelength of electrons, relative to photons, allows for significantly higher resolution...

A scanning electron microscope (SEM) uses a focused beam of electrons as the illumination source which is scanned or rastered over the surface of a sample to generate an image. The shorter wavelength of electrons, relative to photons, allows for significantly higher resolution... read More....

0

17

May 2021

High Pressure/High Temperature

For nearly 50 years, Stress Engineering Services has been providing solutions for clients throughout the energy industry. This includes significant experience in High Pressure / High Temperature (HPHT) applications . These solutions have included testing, analysis, and materials...

For nearly 50 years, Stress Engineering Services has been providing solutions for clients throughout the energy industry. This includes significant experience in High Pressure / High Temperature (HPHT) applications . These solutions have included testing, analysis, and materials... read More....

0

17

May 2021

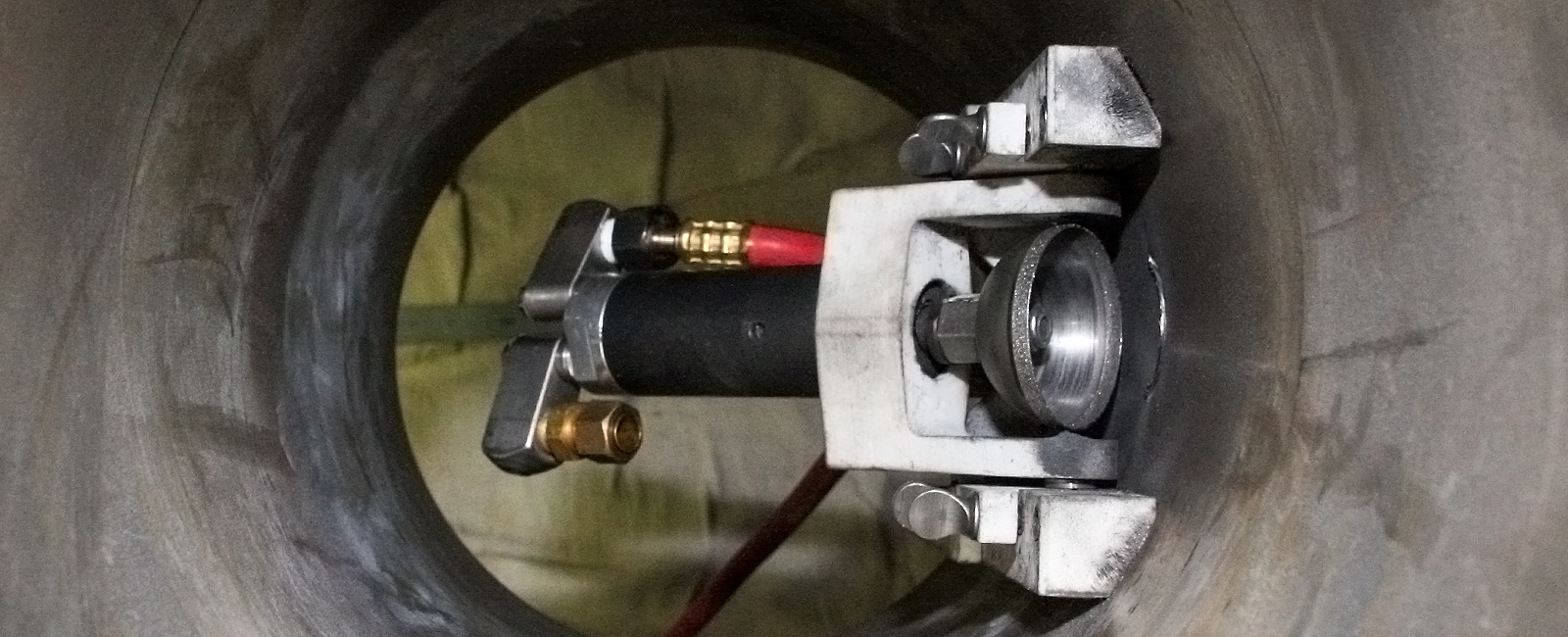

Harsh Environment Testing

To meet emerging needs in the energy industry, we provide a multitude of capabilities and resources that are essential in supporting drilling and production operations in hostile and severe environments. Our materials testing facilities host a full-service fatigue and fracture...

To meet emerging needs in the energy industry, we provide a multitude of capabilities and resources that are essential in supporting drilling and production operations in hostile and severe environments. Our materials testing facilities host a full-service fatigue and fracture... read More....

0

17

May 2021

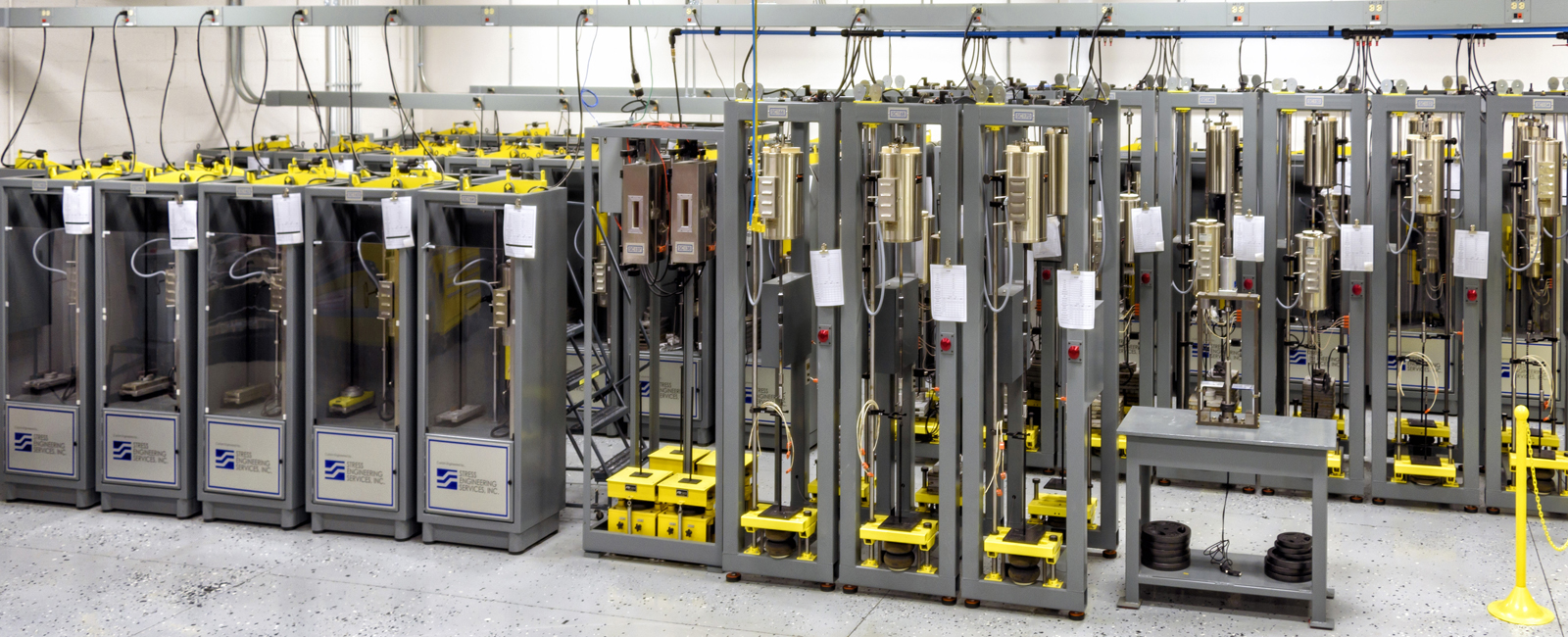

Creep Testing

Stress Engineering Services operates a state-of-the-art creep testing facility as part of its laboratory at the Cincinnati office. The facility is equipped with more than 80 dead load test frames capable of performing steady load testing from a few pounds up to 100 kips at...

Stress Engineering Services operates a state-of-the-art creep testing facility as part of its laboratory at the Cincinnati office. The facility is equipped with more than 80 dead load test frames capable of performing steady load testing from a few pounds up to 100 kips at... read More....

0

17

May 2021

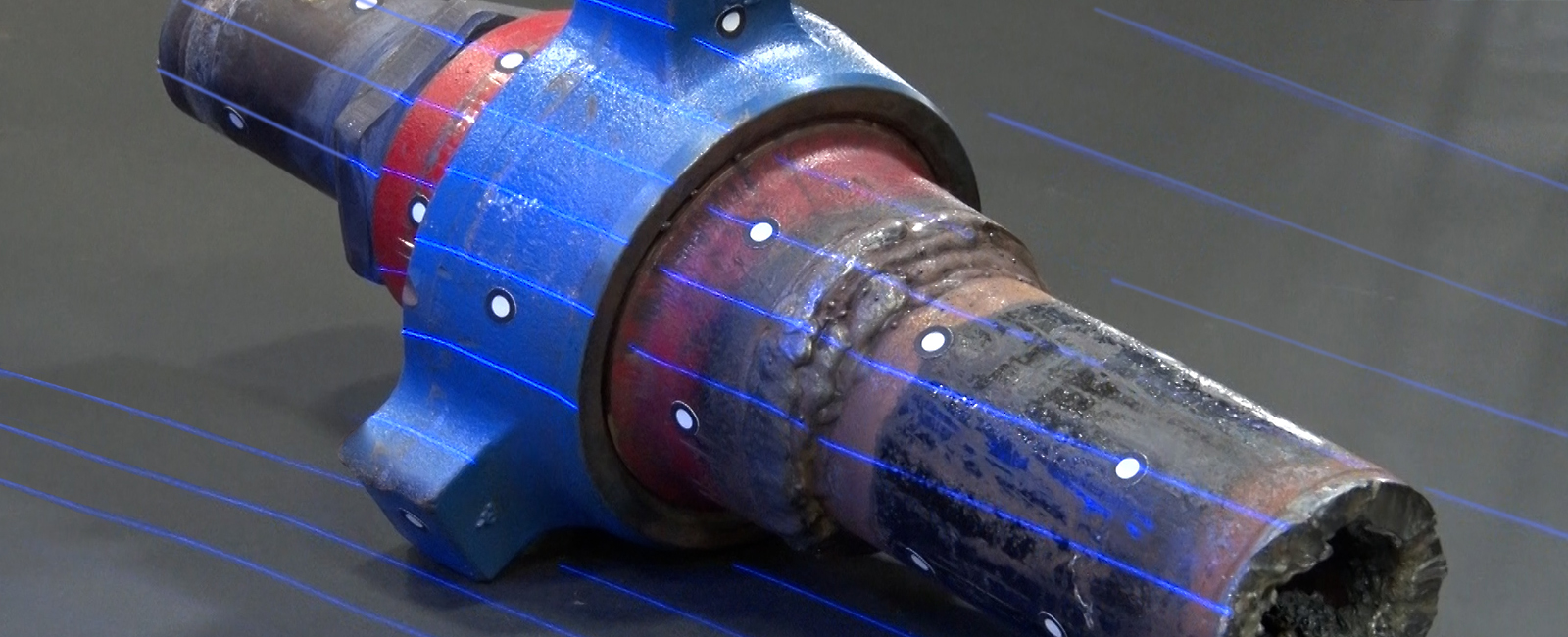

Video and 3D Scanning Technology Services

Fixed Position Laser Scanning Services Laser scanning and photogrammetry scanning are the ideal choice when the objects are large; such as cars, drilling risers, storage tanks, and pressure vessels. Laser scanning’s portable nature enables fast, straightforward and accurate...

Fixed Position Laser Scanning Services Laser scanning and photogrammetry scanning are the ideal choice when the objects are large; such as cars, drilling risers, storage tanks, and pressure vessels. Laser scanning’s portable nature enables fast, straightforward and accurate... read More....

0

17

May 2021

Residual Stress

Corrosive environments are particularly detrimental to metals in tension. In some situations, heat-treating reduces the impact of residual stress, but these procedures often are neither practical nor specified. We can measure residual or ambient stress using strain gages with the...

Corrosive environments are particularly detrimental to metals in tension. In some situations, heat-treating reduces the impact of residual stress, but these procedures often are neither practical nor specified. We can measure residual or ambient stress using strain gages with the... read More....

0

17

May 2021

Non-Destructive Scoop Sampling

Material Condition and Remaining Life Assessment At Stress Engineering Services, we perform material condition assessments on vessels and high temperature plants by extracting small material samples commonly referred to as “scoop” samples. These samples can be taken at...

Material Condition and Remaining Life Assessment At Stress Engineering Services, we perform material condition assessments on vessels and high temperature plants by extracting small material samples commonly referred to as “scoop” samples. These samples can be taken at... read More....

0

17

May 2021